Sustainability - Distillery Efficiency Best Practices

Quick Tips for Savings

To keep growing the sustainability culture in the industry, we have compiled a variety of quick tips to help your team learn how simple changes can make a big difference. We've also put together a short, dense recap of the best practices we've found for energy efficiency in distilling.

Best Energy Practices for Craft Distillers

Key Strategies

- Benchmarking

- Building a sustainability culture

- Continuous improvement

Benchmarking: Where Do You Stand on Energy and Water Use?

Gather up your production volume (TTB reports) and utility bills (gas, water, electric), and use tools like the KPPC SSBI worksheet to assess your top level energy and water use ratios. Tracking these data over time as you change your process helps guide your sustainability journey.

Engage Your Team: Build a Culture of Sustainability for Lasting Change

Your team knows a lot about the ins and outs of your process, so take advantage of their detailed knowledge. Ask if they have ideas for process improvements, and listen to their input on proposed projects. Regularly share detailed data on energy/water usage to keep them thinking about efficiency, and build sustainable growth for your brand from the ground up.

Keep Improving: Completed a Project? Great! What's the Next Improvement?

It's in the name: "Sustainability" itself means planning for the future to ensure longevity. Persistence is critical for success, whether it's after a win or a loss on your last efficiency project. A continuous improvement mindset will maximize your brand longevity and help you continue to drive utility costs down as you grow.

Operations Changes with High Efficiency Impacts

Minimize Steaming Times

Disinfection doesn't take more than a few minutes with steam condensing above 200 degrees F. Ensure your vessels and transfer lines are cleaned and all low points in the system can drain condensate to ensure fast disinfection.

Optimize the Cook and Fermentation

Corn gelatinizes around 185 degrees F, so you can cook at 190 degrees F and still get good conversion of your grain. Dropping your cook temperature from 210 degrees F to 190 degrees F can save 15-20% on heating and cooling costs for every cook. Use thermotolerant, high-gravity yeasts that can tolerate higher pitch/fermentation temperatures to save even more on cooling, and maximize your alcohol yields with thicker beers to increase throughput and total efficiency.

Perform Routine Maintenance

Keeping up with your regular maintenance makes sure your equipment runs efficiently for longer and saves on repairs. Find and fix leaky steam traps and compressed air fixtures. Prevent scale buildup in heat exchangers, boilers and cooling towers.

Upgrade Equipment

It doesn't have to cost a lot to save on energy. Many efficiency upgrades pay for themselves in less than a year, like adding insulation to steam lines or adding waste heat recovery from your air compressor. Heat exchangers, even simple ones like a coil in your stillage tank to preheat water, can help you recover energy that's lost and significantly reduce your operating costs.

Minimize Pressurized Air

Compressed air is the least efficient form of energy around the distillery. Minimize unnecessary use with blowers or mechanical agitators. Reduce your set point as much as you can and save 2% on energy for every 3 psi reduction.

Four Benefits to Proactive Maintenance Routines

Spirits production is an expensive, energy-intensive process. Routine maintenance can be advantageous for a variety of reasons. Get to know your process! Unusual sounds from your equipment might indicate an early stage malfunction, so be proactive and start fixing the problem now instead of later.

- Less downtime: Keeping your distillery equipment in great shape can prevent failures that stop production, maximizing output and making your job easier.

- Safer workplace: Well-maintained equipment will keep running smoothly, which reduces the chances for major failures (like clogged lines requiring pressure relief venting) that could be dangerous to operators.

- High quality and yield: Proactive maintenance will keep equipment like condensers and chillers running well, boosting the amount of spirits produced and ensuring high quality and consistency in your final product.

- Cost savings: Routine maintenance like cleaning heat transfer surfaces, repairing pressurized system leaks, and lubricating pumps/fans could save thousands of dollars each year.

Boiler Efficiency

Steam probably runs most of your distillery - from the cooker to the doubler, most bourbon distilleries add head through natural gas boilers. Make sure your boiler is running well to maximize your energy efficiency and save money.

- Blowdown: Prevent scale buildup by optimizing blowdown frequency. Scale can reduce heat transfer efficiency by 5% - minimize by monitoring TDS and looking for solids in your boiler's sight glass.

- Burners: If your boiler has a sight glass to check the flames, get in the habit of looking in - heavy soot buildup in the sight glass and irregular or unusual flame patterns might mean it's time for maintenance.

- Monitoring: Check the flue gas (exhaust) temperature? If it increases over time, it means less heat is going to make steam and more leaving through the ceiling - time to get service or tuning to reduce your gas bill.

~90% of fuel used in distilleries goes to heating water and making steam.

Steam Disinfection

Steam is one of the biggest consumers of energy in the distilled spirits industry, so using less steam in processes like tank disinfection (where you don't return the condensate to the boiler) can have a big impact on your bottom line. Check out the tips below to see how your facility can save.

- Clean well before steaming: Effective steam sterilization requires a clean surface. Grain debris can protect bacteria from steam and cause contamination. Consider using butterfly instead of ball valves for mash lines since they are easier to clean.

- Crack open low point drains: Steam needs to condense directly onto a surface to ensure that it is decontaminated. Make sure condensate that collects while steaming has a way to drain from the pipe/tank to ensure efficient disinfection.

- Find and fix deadlegs: Dead-end piping branches, like tee fittings or three-way valves, can be hard for steam to enter. Ensure any dead-end branches are no more than three times as long as the diameter of the pipe.

- Reduce steaming time: If you're doing it "right," it should take less than a minute above 200 degrees F for condensing steam to kill the bacteria that contaminate your beer - so you might be able to significantly reduce steam usage and disinfection time by following these tips.

Compressed Air Savings

Air is used at pressures throughout the distillery, and it takes a lot of energy to make it. Maximize savings by making sure your compressed air system is in good shape.

- Fix leaks: Leaks pop up over time, so having a leak inspection and repair plan can save up to 20% energy on air.

- Reduce setpoints: Reducing air pressure setpoint by just 2 psi can save 1%.

- Check traps often: Air trap maintenance pays for itself in less than 2 years.

- Turn off unused lines: Closing off lines to inactive equipment can reduce energy used by the compressor.

Tips for Finding Compressed Air Leaks

Compressed air is used throughout the distillery, for operating control valves, moving fluids around, and sometimes even mixing tanks. It takes a lot of energy to squeeze air to high pressures, so fixing leaks can have a significant impact on energy use in the distillery.

- Look: Fast-moving air leaking from a pressurized system could push things around, so look for unexpected gaps in dust settled near air lines.

- Listen: Leaking air from high-pressure lines or fixtures moves fast, so sometimes you can hear it as hissing or whistling. Try listening when other equipment isn't running for a better chance to hear it.

- Don't touch: High-pressure air can be surprisingly powerful, so it's best not to use your hands or exposed skin to search for leaks.

- Use tools: Looking and listening won't always catch leaks, so sometimes you need more tools. Ultrasound detectors are the best choice, but you can also use air flow testers or a spray bottle with soapwater and watch for bubbles that indicate there are leaks.

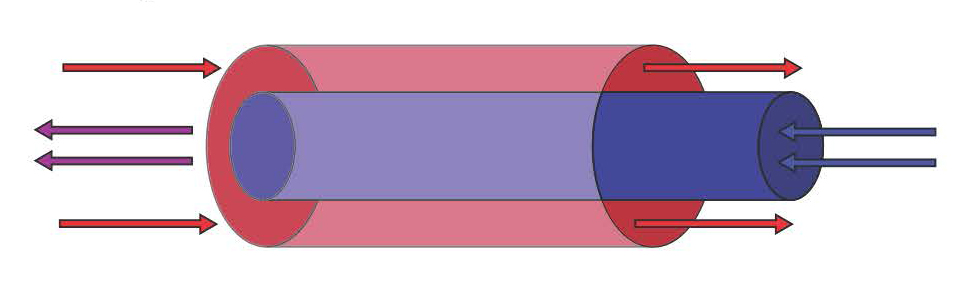

Shell and Tube

- Great for condensers (including beer heater)

- Not easily expandable

- Smaller footprint

- Condensed liquid exits at low point shell

Assuming that:

- Cooler water coming in is ~60 degrees F

- Vapor temperature coming in is ~178 degrees F

- Condensate proof is ~125 degrees F and at 90 degrees F

Baseline needs ~75 sq. ft. of tube surface area per 1 GPM of condensate.

If cooling water is 10 degrees F warmer coming in:

- Need 15% more area

- OR need 30% more cooling water flow

If vapor proof increases by 10 degrees:

- Need ~25% less area

Double Pipe

- Great for mash cooler or stillage heat recovery

- Easy (but costly) to expand as you scale up

- Larger footprint

Plate and Frame

- Great for chill filtration

- Lower cost and high efficiency

- Easily expands as you scale up

- Calculating heat exchange capacity is not straightforward, so work with your supplier

Estimates made from JBBI distillery specifications and design. Please note that heat exchanger design is complex, and this sheet provides a rough estimate only. Always consult with your equipment provider before purchase.

Heat Exchanger Capacity

Estimating Capacity Needs

Heat exchangers are rated by their capacity - the amount of energy per hour that they can transfer between fluids. First, estimate your required capacity:

- For each GPM of condensed distillate, need ~260,000-310,000 BTU/h capacity

- For liquid-liquid exchange, need ~210,000 BTU/h for every ~25 degrees F in temperature change of process fluid

The rated capacity for a heat exchanger is given for specified conditions, like cooling water from 120 degrees F to 100 degrees F using water at 70 degrees F. These conditions will likely be different from your needs.

Heat will transfer faster and you might get away with a smaller exchanger if:

- The temperature difference between the hot fluid (distillate, mash or stillage) and the cooling water is larger than specified conditions

- Distillate is condensing in the exchanger

Heat will transfer slower and you might need a larger exchanger if:

- The temperature difference between hot and cold is smaller than specified conditions

- One or both of the fluids are more viscous (thicker) than specified fluids

Equations to Estimate:

q - how many BTUs (capacity)

m - how many pounds per hour

delta Hv - heat of vaporization, ~650 BTU/lb at 130 proof

Cp - heat capacity, ~1 BTU/(lb x degrees F)

delta T - how many degrees F the liquid needs to change

Condensing: q=m x delta Hv

Heating/cooling: q=m x Cp x delta T

Double Pipe

- Great for mash cooler or stillage heat recovery

- Larger footprint, easy cleaning

Shell and Tube

- Great for condensers and beer heater

- Smaller footprint

- For condenser, liquid exits at low point

Plate and Frame

- Great for chill filtration

- Lower cost and high efficiency

- Easily expands as you scale up

This information is for reference in spirits production, always consult with your equipment supplier before purchase.

Why Monitor Gelatinization?

Different batches of grains can have different starch structures, due to variations in watering, climate and storage. This means it might take more or less energy or time to get good extraction and gelatinization from batch to batch.

Tracking gelatinization in your cook can make sure you maximize yield, consistency and energy savings.

How Do I Monitor?

Iodine staining indicates the presence of gelatinized starches by binding and changing color, which only happens with gelatinized starch, not converted sugars or unextracted starches.

The Iodine Test

- Grab a small sample of mash, just a tablespoon or a few mL

- Add a few drops of potassium iodide/iodine solution and mix

- Track the color change over time during your mash cook

- It should go from the yellow/red to black when it's gelatinized, and back to a yellow/red color when it's converted to sugar

The colors you see may not be identical to this chart, but the key idea is to track this frequently so you can see if one run acts differently than your normal.

Understanding Malt CoAs

All malt metrics are connected, but here are a few of the key metrics to monitor on the malt CoA to ensure efficient starch conversion:

- Diastatic Power (DP)

- Total activity of starch-degrading enzymes

- Related to protein content

- For distillers, target should be >150 degrees L

- Alpha-Amylase (AA)

- Activity of a-amylase (enzyme) that rapidly digests starch in the mash

- For distillers, target should be >70 D.U.

- Free Amino Nitrogen (FAN)

- Main source of nitrogen for yeast nutrition in fermentation

- For distillers, target should be >200 mg/L

Consistently keep track of information in the malt CoA so you can be ready for changes in malt quality that might affect your conversion and fermentation.

Tips and Troubleshooting

Consider adjusting the peak cook temp/time if you consistently reach peak gelatinization before you finish

- Benchmark everything! Energy, water, chiller usage as well as QC, sensory, known change in grain source, variety or age

If it doesn't revert to yellowish with iodine:

- Understand the CoA of your malt and keep track of provided metrics

- Check your malt addition temp (should be below 160 degrees F to keep enzymes functional)

If you add pre-malt or enzymes, you may never stain fully black with iodine as the starches can be digested throughout the cook, so you still need to check that you're getting good extraction with a hydrometer (Brix or SG) at the end.

Normalize expectations to YOUR process, and watch for deviations to adjust parameters based on your needs as you continue production.